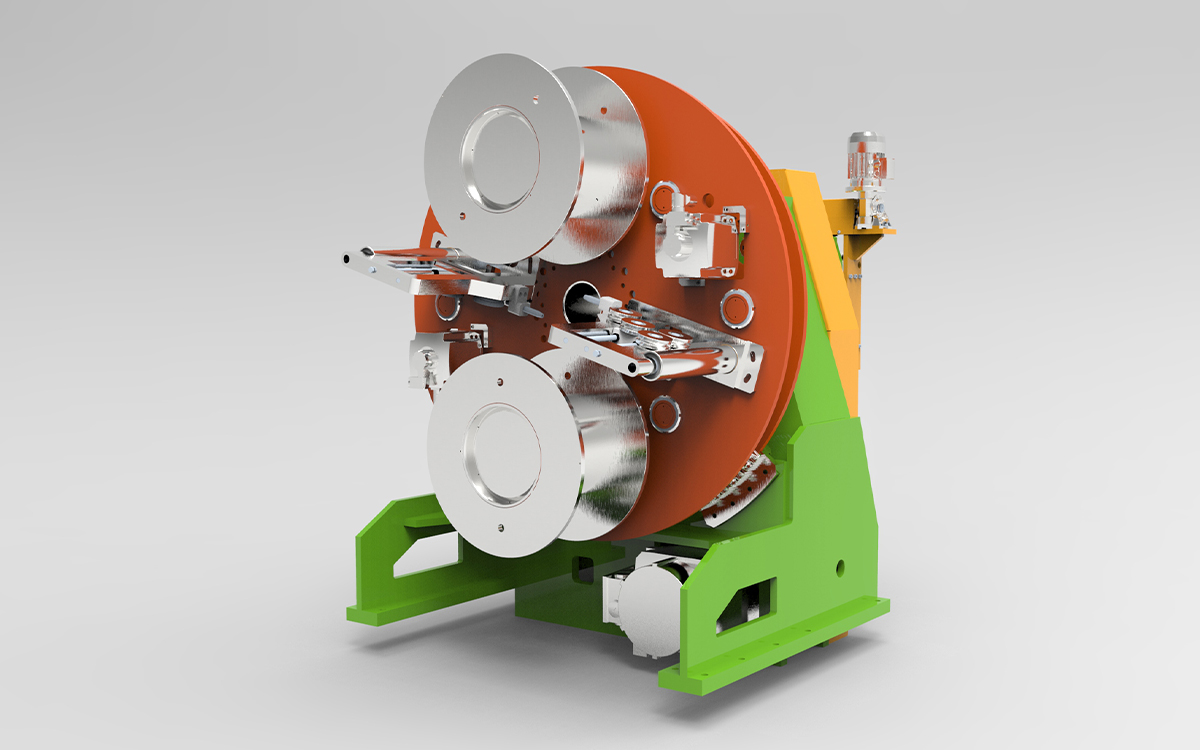

RUBBER HOSE FIELD

Spiraling Machinery

Main Features, Benefit and Strenghts

The Spiraling Machinery is full-made in painted steel; it bases on a stand-alone base.

The plateau is central-supported by a raft with ø 250mm max hose lane. On the plateau-side, there is the gear which engine the wire reformer. Plateau’s braking system is a tire-type model, for both stabling and emergency stop. Gears run through timing belts HTD type, managed by two vector engine motors.

The Wire Ending-up alarm or wire breaking one is made by Steel rings, isolated, which switch off the contact in case of wire breaking.

To reduce working-noises and protect worker, the machinery places inside a soundproof booths.