RUBBER HOSE FIELD

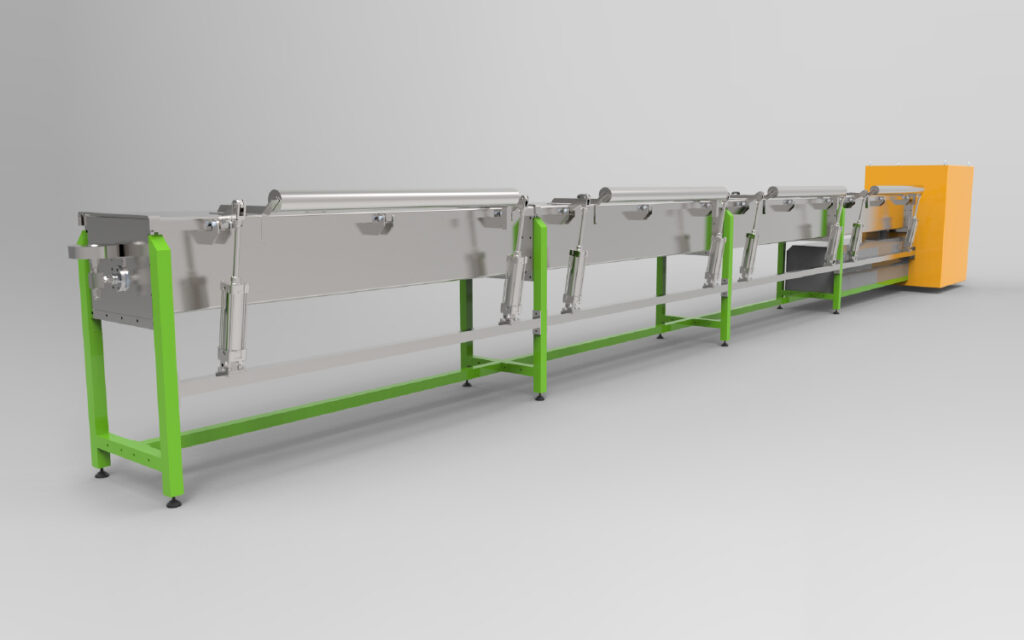

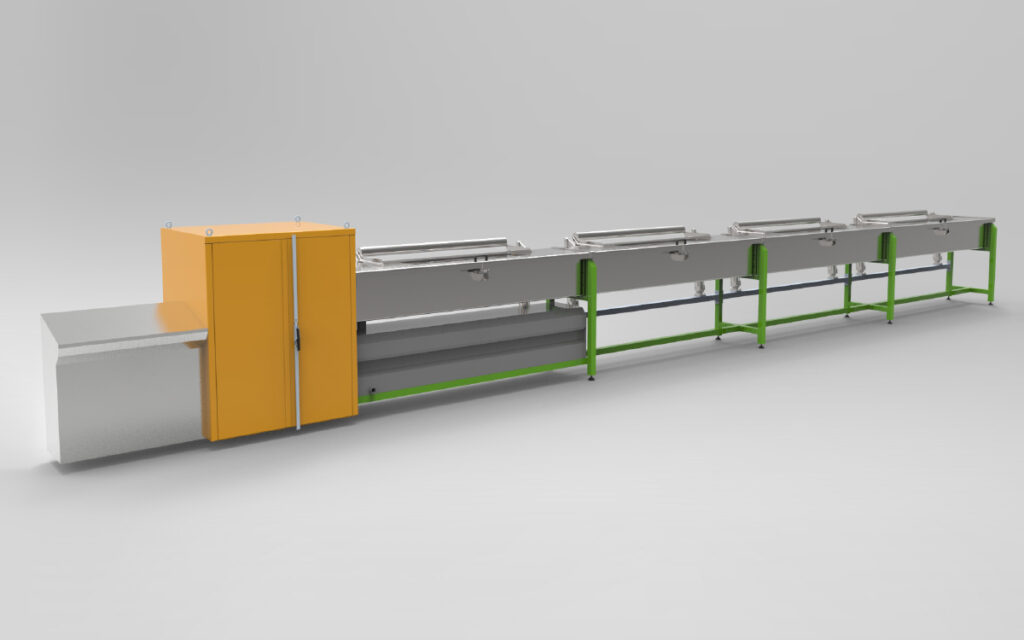

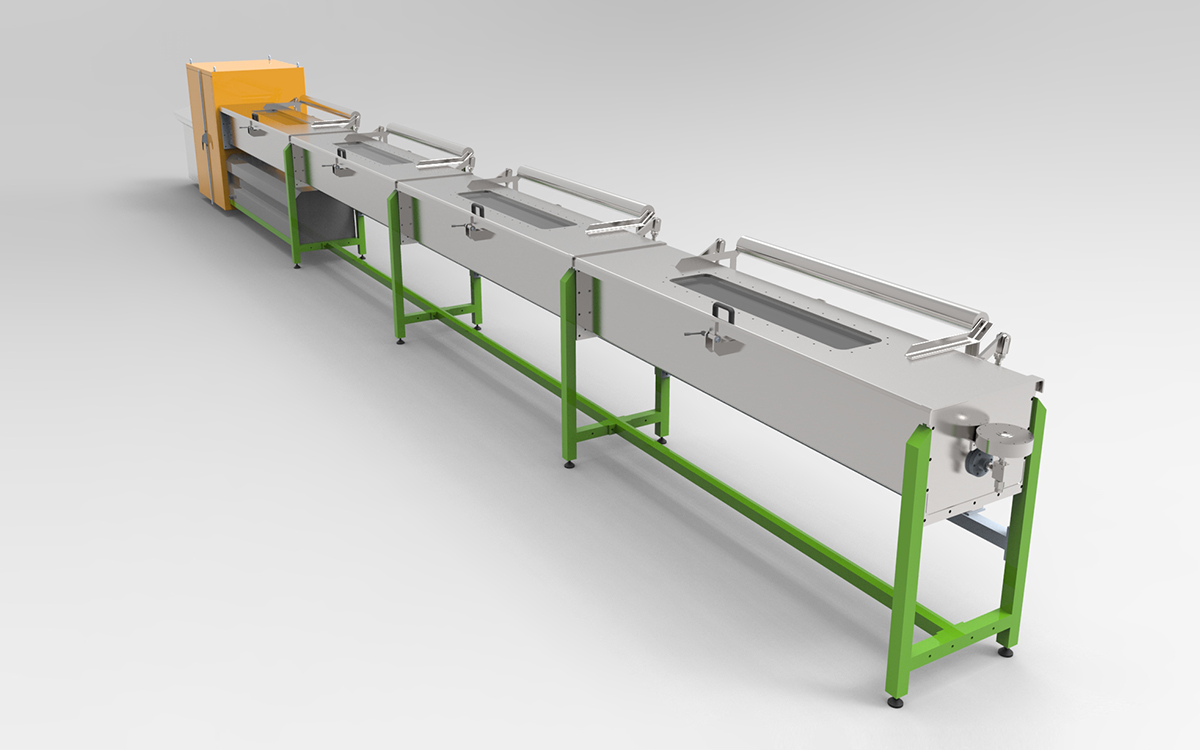

Rotary Test Bench

Main features, Benefits and Strengths

Alci solution designed to test high-pressure hoses. The machine consists of the following parts: the head where the loading pump is installed, the filtrating system which manages the workflow, the high-pressure pump, the electric panel and a system to connect the hose.

The frame is made of a painted steel modular structure. The testing tub is made of painted steel and includes the tub’s compartments made of press-folded sheet metal. The tub’s lids are made of sheet metal and they have a porthole in the central part in laminated glass for the inspection. The lids opening and closing is carned out through a centralized pneumatic system.

The internal surface of the tub is covered with plastic material. In the back, there is a junction where to connect the ending part of the pipe to be tested.

Downstream of the junction there is a pneumatic control valve that opens or closes the circuit during the testing phase.

The plumbing for testing consists of a centrifugal loading pump with a presscontrol of 1’’, ceramic hydraulic intensifier with double plunge stroke with 1/20 multiplication ratio, maximum pressure on the hydraulic side 190 bar, maximum flow at 3800 bar liters 3.9 l/minute. Hydraulic control unit with double pump for testing. The machine is equipped with a pressure transducer that measures the pressure inside the tube.