RUBBER HOSE FIELD

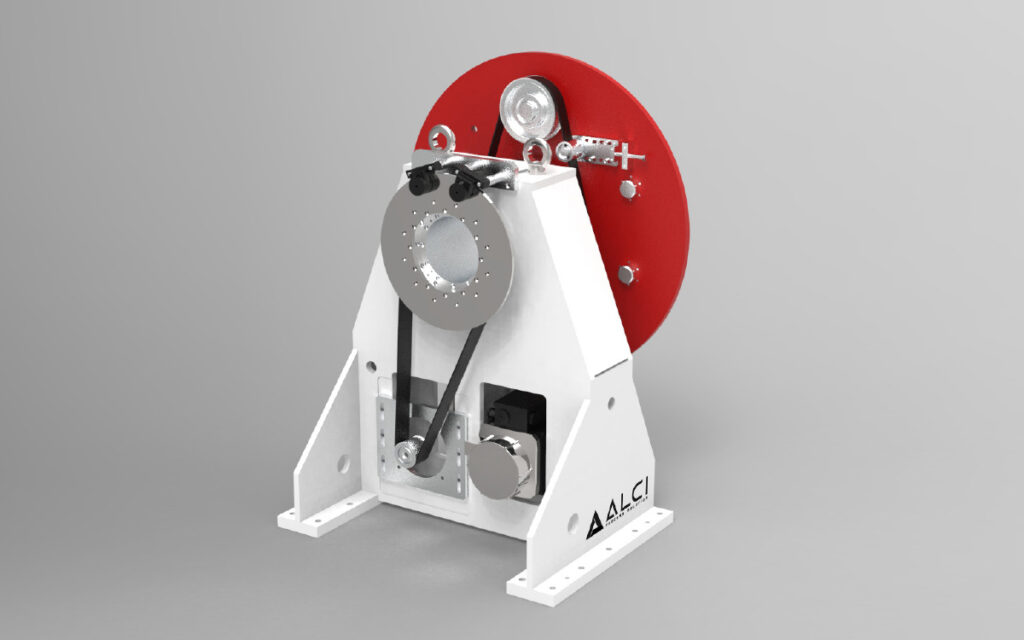

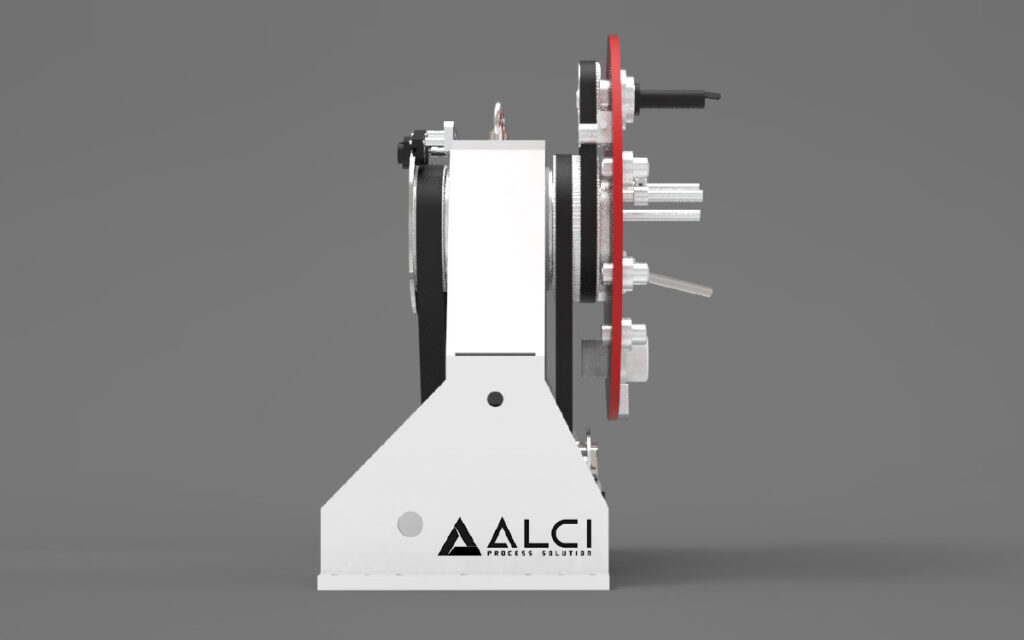

Eccentric Unwrapping Machine SE250

Main features, Benefits and Strengths

The eccentric unwrapping machine is designed to unwrap helically polyamide tapes (bandage) that are located around rubber pipes. This feature is obtained from the rotation of the rotating unit around the pipe axis and the shift of pipe along its axis. The pipe inside of the central part of the machine is gradually unwrapped thanks to the bandage passage into rollers that are fixed on the rotating unit. The collected bandage is wrapped on a motorised shaft that is fixed on the rotating unit, too. The motion is given by asynchronous electric motors on the support frame of the machine.

The machine is made of:

- Support frame

The structure consists of sheet steel S235JR welded and painted according to RAL agreed with the customer. The main feature is to support the rotating unit, the transmission and the electric motors. The structure includes mounting brackets to secure the machine to the ground.

- Rotating unit

This rotating part of the machine consists of a central tube placed on ball radial bearings, on which is fixed an aluminium alloy disc that supports return shafts and the motorised reel-holder shaft.

- Collecting unit and reel holder

This part of the machine consists of a motorised shaft and transmission equipment where the material is collected and wrapped. This unit collects the bandage to create reels.