RUBBER HOSE FIELD

Bending Machinery

Main Features, Benefit and Strengths

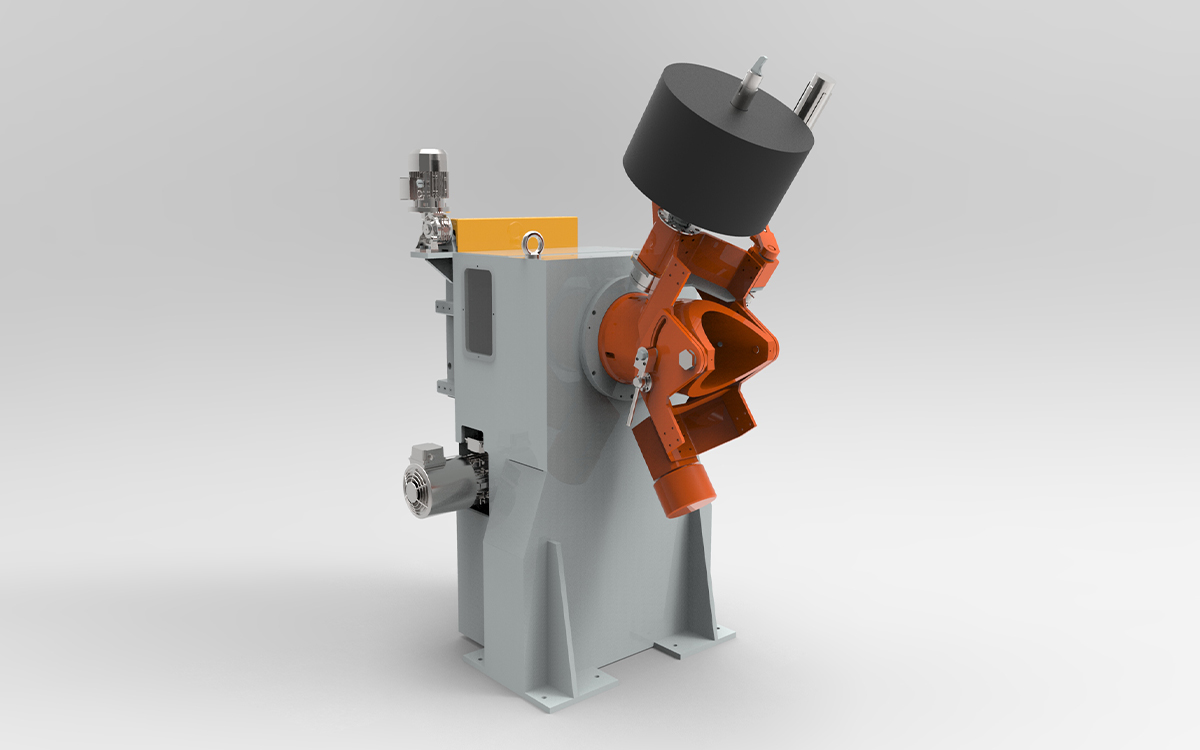

TF250 designed and built to be planted for supporting an existing plant too. Its structure, surrounding by a containment cage, made in Fe360. TF250 composed by: a head to bind for the rubber substrate application, by a rotating arms called “plateau” for rubber, canvas, bandage, (etc. etc.) applying, and by a sliding mandrel. Plateau arms equipped with brake for continuous tension of tape on mandrel, both automatic and manual use. TF250 support system can be planted along the entire electrically line; operator can manager it by PLC.

The entire plateau set will perfectly suit at the plotting rotation speed range. An acoustic signal advice about rubber-out roll: a simultaneous arrest happens and keep the machinery in a safety condition. The machinery also known “electrical axis”, because an autonomous and independent ones from the others drive each plateau. A PLC manages all motors and let them working in harmony as if they are connected mechanically and jointly with the entire line plotting.

Settings:

- Strip rubber’s Shaft Referral Inclination is a function of the desired pose and surmounts.

- Setting about rubber’s intensity brake roll for a right tension of rubber posed on mandrel.

- Rubber step adjustment.

- Line speed adjustment.

- Safety devices management.