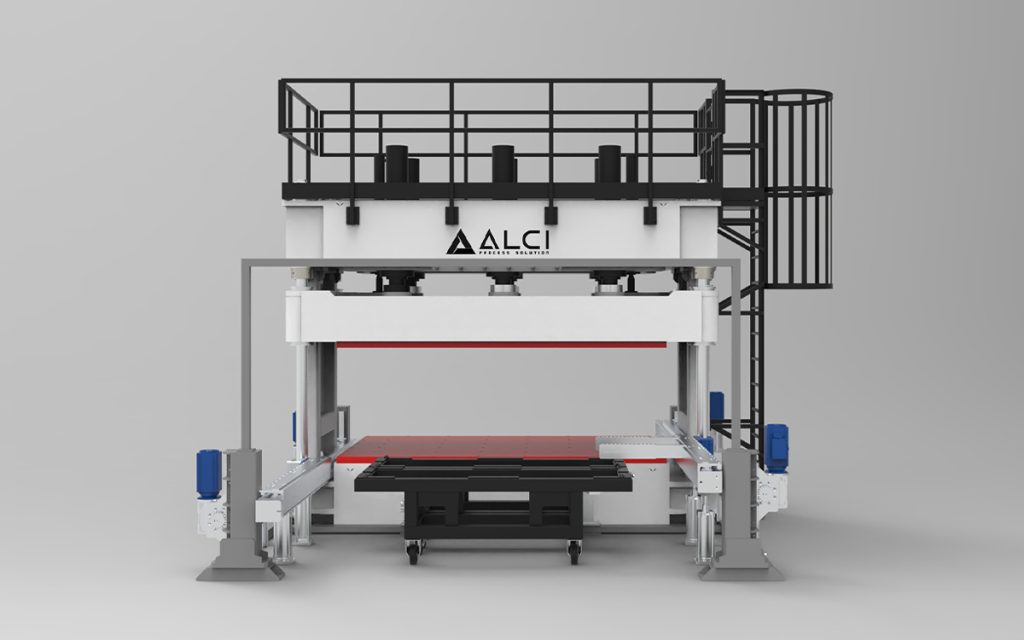

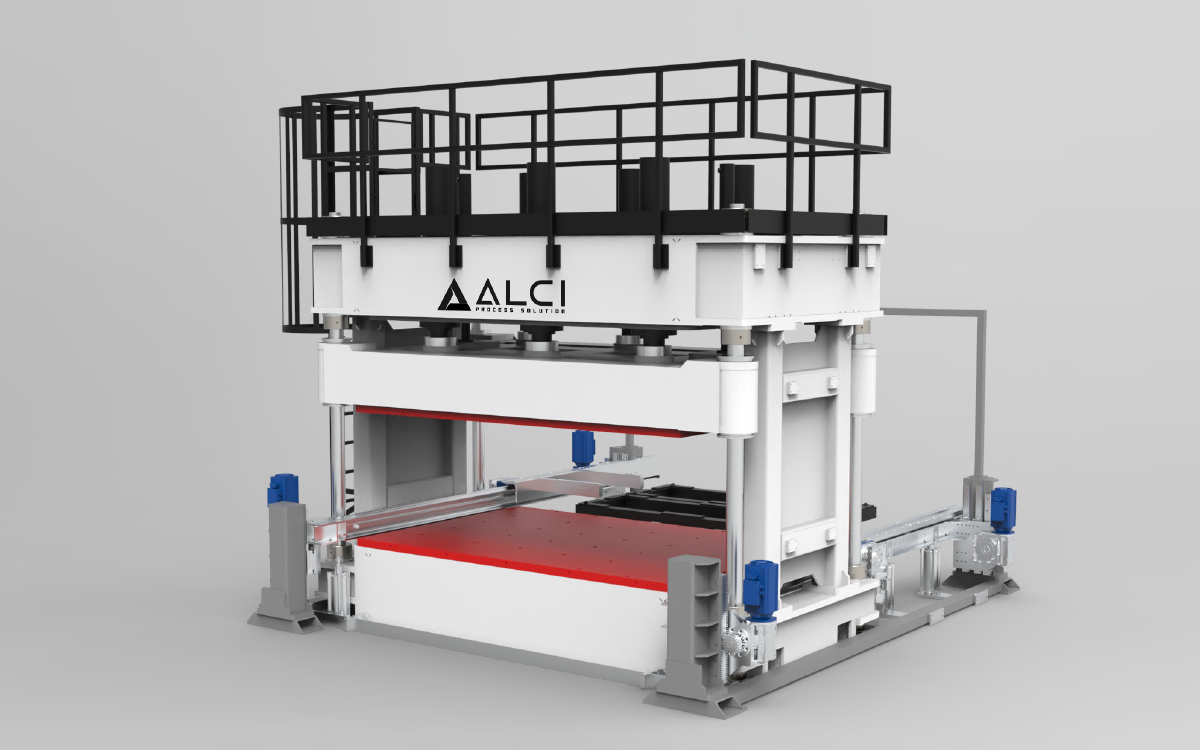

Automatic Machines

Automatic Pressing Machine with Hot Plates

Main features, Benefits and Strengths

The automated press with hot plates is designed to mould composite laminates installed on a mould and subjected to temperature and pressure programs.

The frame of the machine consists of a metal structure, which supports and accommodates the stretching cylinders, the moving surface on which the pressure is weighed.

The support and push surfaces that in the closing create a pressurised chamber are made of a single sheet of normalised and certified steel shaped to ensure a geometric offset that ensures an adequate degree of parallelism, flatness and roughness.

The heating circuit of the moulds is obtained from the surfaces produced.

The machine is equipped with a universal transfer device which is able to accommodate the mould and transfer it to the pressing area.

The access to the loading and moulding area is blocked by guards such as fixed shelters in combination with interlocked mobile shelters.